Elevating 3D printing: A partnership for stronger parts

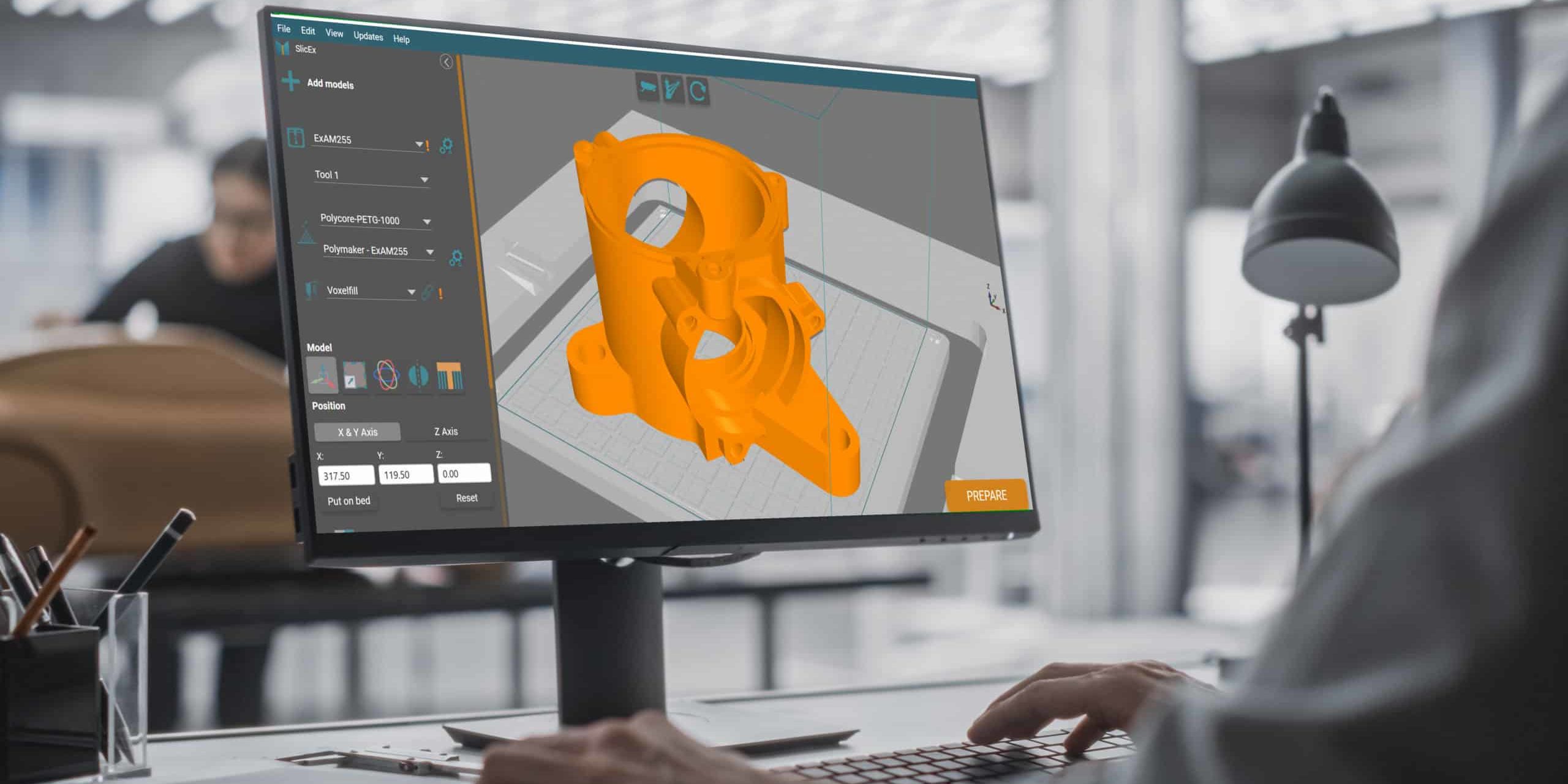

The German AIM3D GmbH and the Danish Create it REAL want to announce a partnership to integrate and realize the patent-pending Voxelfill print strategy in a dedicated software solution. AIM3D has taken a new approach to overcome inhomogeneous strengths and scores with defined selective densities in the component. The partnership around Voxelfill and capability development will be realized through a dedicated slicing software solution, SlicEx, and an integrated Voxelfill plugin for AIM3D’s ExAM printers. The objective is to enable the Additive Manufacturing industry to overcome the disadvantages in terms of tensile and bending strength and very brittle behavior along the Z-axis. The Voxelfill process is particularly suitable for the 3D printing of plastics and fiber-filled plastics. Still, it is also suitable for the 3D printing metal and ceramic components using the CEM process. In general, there are great advantages for the AM industry due to the higher construction speed and the filling across layers.

AIM3D’s CTO, Clemens Lieberwirth, expressed his satisfaction with the collaboration, stating, “Create it REAL offers not only powerful and user-friendly software but also first-class support. The Create it REAL team is always ready to help, answer my questions, and resolve my concerns. We appreciate the fast and professional communication as well as the open-minded teamwork.”

Clemens Lieberwirth further emphasized the benefits of the collaboration, stating, “The reason why we chose to partner with Create it REAL was their flexible business model based on fair and transparent pricing, an existing product with the opportunity for deep user-driven adjustments and add-ons. We are very happy about the partnership with Create it REAL and would recommend them to anyone looking for a reliable and advanced 3D printing software solution.”

Jacob Nissen, CEO of Create it REAL, expresses his excitement about the partnership: “AIM3D is an ideal partner, backed by a strong academic background and a solid theoretical foundation. Their clear vision aligns perfectly with our capabilities, enabling us to collaborate effectively in achieving their goals.”

The partnership between AIM3D and Create it REAL promises to drive innovation in the 3D printing industry, delivering cutting-edge solutions to meet customers’ evolving needs.

The SlicEx 3D printer software and Voxelfill plugin will be demonstrated at FormNext, step by the AIM3D or Create it REAL booth to learn more. Contact us to arrange an interview in advance or at FormNext.

Further information

For more information about AIM3D GmbH, visit www.aim3d.de

For more information about Create it REAL, visit www.createitreal.com and www.realvision.pro

Press Contact:

Clemens Lieberwirth

CTO, AIM3D GmbH

Email: [email protected]

Phone: +49 (0) 381 / 36 76 60 92

Mette Kristensen

Marketing Manager

Email: [email protected]

Boilerplates

With the aim of drastically reducing the cost of additive manufacturing, Dr.-Ing. Vincent Morrison and Clemens Lieberwirth founded AIM3D in 2017 as a spin-off from the University of Rostock.

The founders had previously worked with a variety of different additive manufacturing processes at the university, covering plastics, as well as metals and ceramics. During this time, they experienced how the industrial application of additive manufacturing processes often failed due to high material costs and, in particular, when it came to the production of metal parts, also due to high machine costs.

For this reason, AIM3D was founded not just with the aim of simply building another 3D printer but to overcome the limitations with respect to materials and to revolutionize the additive manufacturing market from a cost point of view.

The result is a multi-material printer that is much more cost-efficient than any currently available metal printer and, at the same time, offers customers an unprecedented choice of materials.

Create it REAL is a company that is passionate about enabling creativity through 3D printing. The company has developed REALvision Core slicer technology, which is a cornerstone of its offerings. The highly skilled 3D printing team is based in Aalborg, Denmark, and has been leading the industry for over a decade. Create it REAL aims to make 3D printing accessible and enjoyable for everyone and positively impact the industry. The company’s Embrace suite for orthopedic applications includes CAM solutions for insoles, corsets, and seats, providing a range of opportunities for businesses in the healthcare sector seeking to mass-customize high-quality products for individuals.

Create it REAL offers top-notch software solutions and expert consultancy services to help customers maximize their 3D printing potential. With REALvision Pro and the company’s professional consultancy services, customers have all the tools they need to turn their 3D printing aspirations into reality. Create it REAL invites customers to experience the power of the company and unlock the full potential of their creativity.