Stronger 3D prints with smarter slicing

Achieve strong 3D printed parts effortless with REALvision Pro slicer software for 3D printers

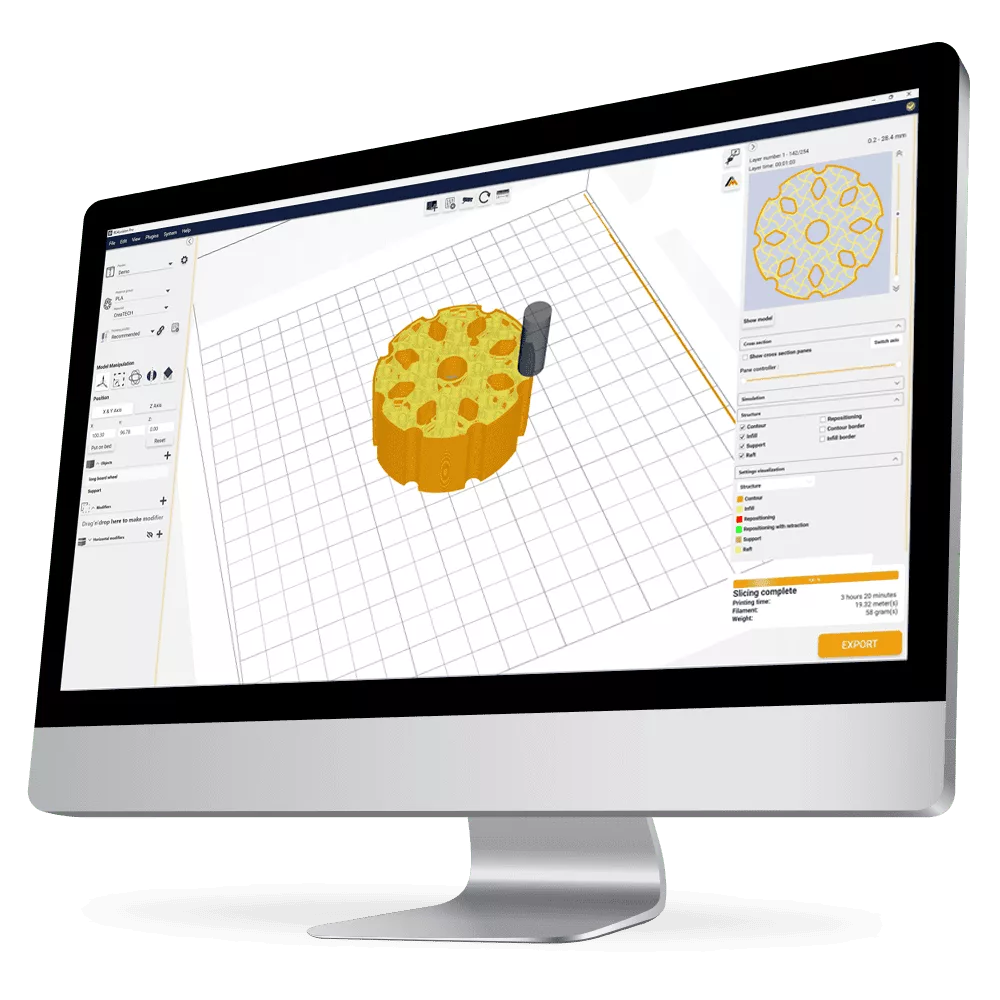

Design your 3D objects and transform your 3D designs into stunning prints with our powerful and user-friendly build preparation software, REALvision Pro. Seamlessly import your 3D CAD designs and visualize your 3D-designed models as 3D prints.

Whether you’re creating prototypes or product designs, achieve superior 3D printing results, and take your 3D design projects to their full potential.

REALvision Pro features smart limits in Machine, Material, and Quality settings. That helps your 3D content stay inside the balanced triangle between speed, quality, and strength. Smart settings support the beginner in quickly bringing great product design to life without complicating the experience. The expert user can dig into the more than 150 settings to take full advantage of their three-dimensional printer and hold complete control within smart limits.

If you use 3D printing services like Shapeways or Formlabs but would like to 3D print yourself for added customization and scalability, REALvision Pro is the 3D printing software you need to print your 3D CAD designs. Whether you’re producing geometric designs, customized parts, or printed models for mass customization, REALvision Pro streamlines the process, ensuring the highest quality 3D prints.

Additionally, REALvision Pro is compatible files from platforms like Tinkercad or Thingiverse, allowing users to download free models or share their creations within the vibrant 3D printing community.

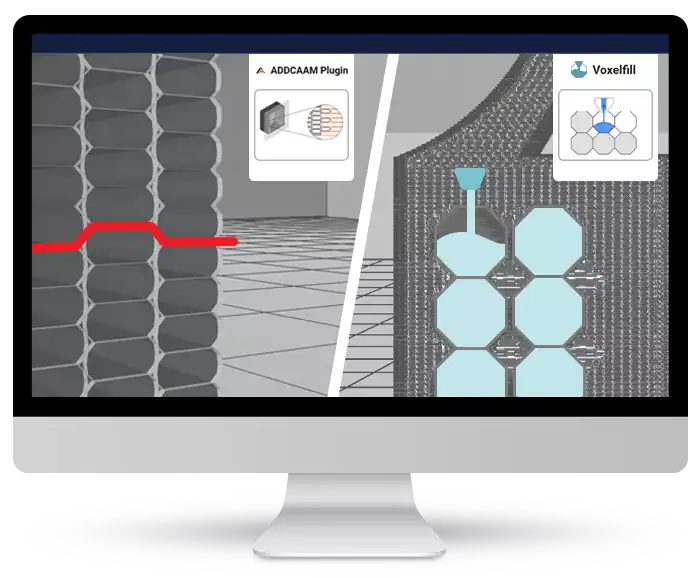

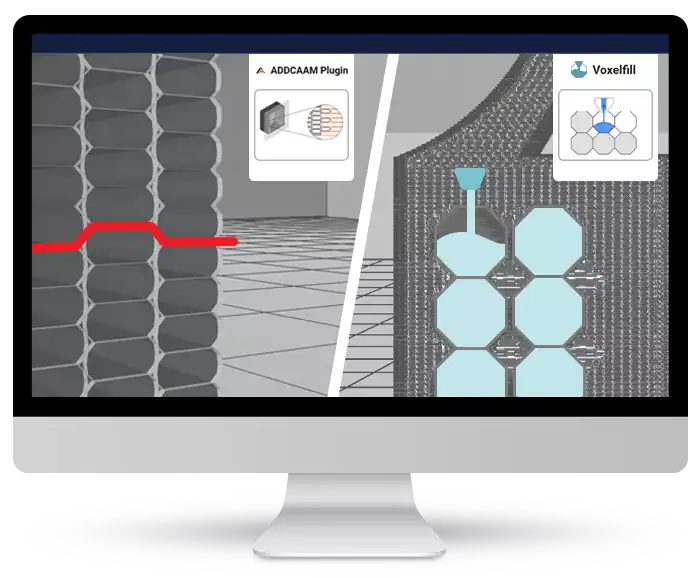

With advanced features like 3D infill patterns and extruder calibration, you can fine-tune every aspect of your printing for exceptional results. From your design software to REALvision Pro printing software, it empowers users of all skill levels to fabricate their vision, whether at home with a hobbyist 3D printer or in professional settings for rapid manufacturing.

Unlock the full potential of 3D printing technology with REALvision Pro – the cutting-edge 3D printing software designed for professionals, engineers, and hobbyists alike. Whether you’re using a desktop 3D printer like the popular Bambulab, Prusa i3, Creality, Anycubic, or Monoprice, or more advanced 3D printers like Ultimaker, MakerBot, or 3D Systems, this intuitive software turns your 3D design or 3D model into optimized G-code for precise extrusion, efficient deposition, and seamless fabrication of three-dimensional objects.

REALvision Pro is built for additive manufacturing and rapid prototyping. It supports fused deposition modeling (FDM) or fused filament fabrication (FFF), ideal for crafting 3D models, prototypes, and production-grade plastic parts from materials like PLA, ABS, Nylon, and other extrusion materials (excluding resin and metal powder). Whether you’re designing with CAD software like Autodesk, SolidWorks, SketchUp, or beginner tools like Tinkercad, REALvision Pro ensures a smooth workflow from 3D design to the printing process.

Enhance your 3D printing experience with seamless integration of a slicer that leverages the best of your 3D scanning and reverse engineering workflows (cad-cam). Using a 3D scanner or industry standards 3D modeling software like Blender, FreeCAD, or SketchUp, Solidworks, Autodesk inventor… you can create customizable 3D models from a wide range of applications (export in STL). REALvision Pro ensures the best 3D printing results with optimized settings for different 3D printers and simulation rendering before 3D printing. .

If you are using Stereolithography (SLA), Selective Laser Sintering (SLS), or Direct Metal Laser Sintering (DMLS), REALvision Pro will make you reconsider using FDM. It delivers exceptional results and makes FDM a top contender for high-quality 3D prints.

For those in the open-source community or using RepRap style machines, REALvision Pro is fully compatible with other open-source software and 3D printers. Plus, it integrates with cloud-based platforms for easy printing services. Whether you’re printing with PLA, thermoplastics, or biodegradable materials, REALvision Pro’s slicing software guarantees the most efficient printing process for every 3D printer filament type.

REALvision Pro is an alternative to slicers like Cura, Simplify 3D, Superslicer, and Slic3r, with the added value of strength. It offers flexible slicing options for users of all skill levels. Achieve the ultimate strength and surface finish for printed products, whether for figurines, scale models, or functional prototypes. With your 3D printers stepper motors, extruders, and tooling finely calibrated for precision, REALvision Pro ensures that the entire printing process from design to post-processing is a success. Whether you’re creating 3D printed parts for prosthetics, mechanical design, or 3D printed models for animation software, REALvision Pro brings your digital design to life.

High-end professional slicer – we take end-to-end responsibility for the entire 3D printing process.

High-end professional slicer – we take end-to-end responsibility for the entire 3D printing process.