3D printing supports: Five ways to success

Support structures are often the golden key in FDM 3D printing. They help to increase the overall strength of your 3D print and allow you to print in difficult angles that would otherwise end up in messy structures.

However, quite often they are also the evil of FDM 3D printing. If supports are not set correctly, they can be waste of material, time and money. Unnecessary supports can be difficult to remove from the prints and leave rough surfaces behind. Missing support structures will result in bad quality 3D prints.

You need to know how to build them up and you need a software that makes it possible to customize it to your 3D model. That’s why REALvision Pro gives the user several options to adjust support in the most optimal way considering the model and the purpose.

Here are five highlights on how to set support in REALvision Pro – so you never have to worry about what comes out of the printer.

Automatic support structures - enhancing overall strength

When you import a 3D model into REALvision Pro, support will be set by default everywhere where it is necessary. Depending on the filament profile, this mostly means everywhere where the overhang angle is larger than 55 degrees. Of course this value can be changed. This is the fastest and easiest way to set support structures to your 3D model.

Buildplate-only support structures - strength with less support

Sometimes less is more. You can also decide to use the Buildplate-only support option in REALvision Pro. In this case support will only be created for overhangs that can be projected directly down to the buildplate, without intersecting the object. The maximum overhang angle can be changed easily in the printing settings/support parameters.

Paint-on support - in total control of the finest details

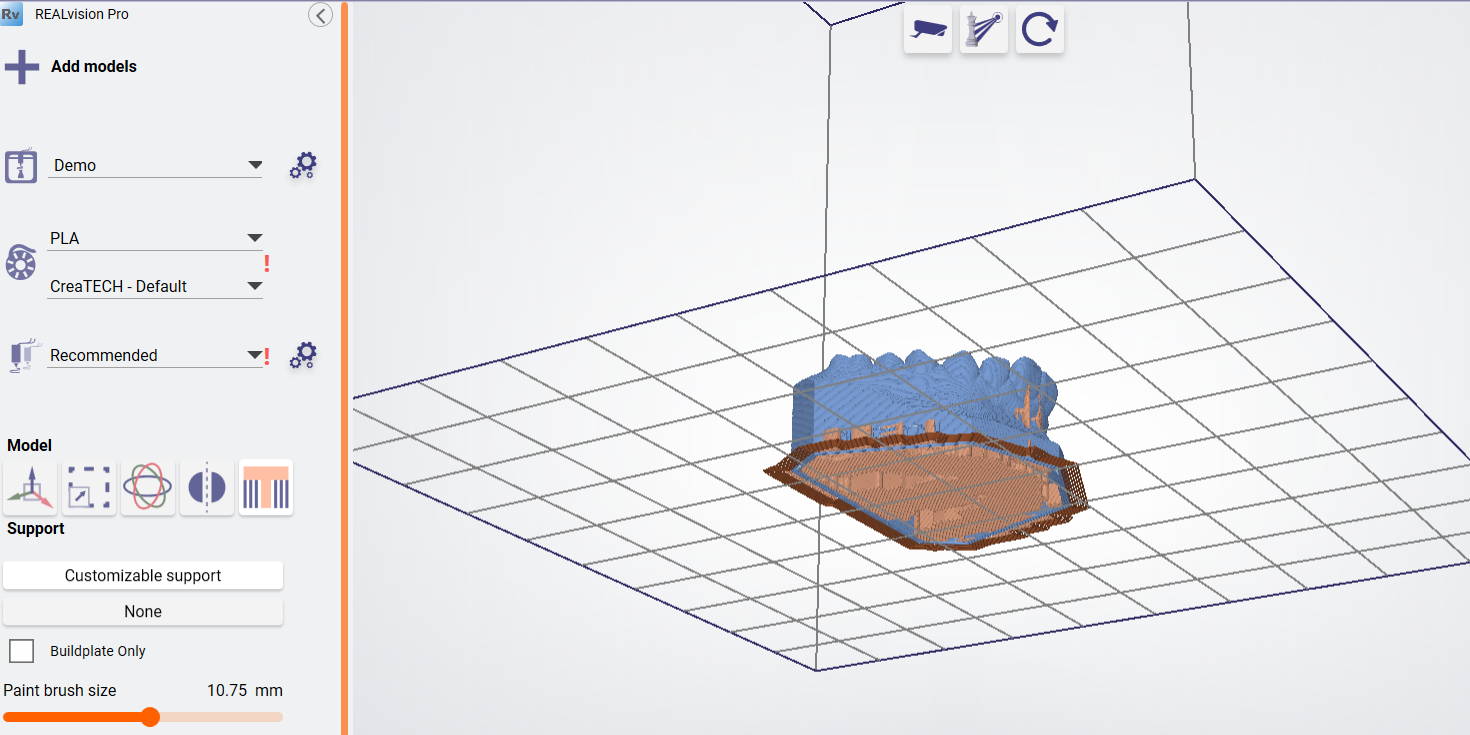

The paint-on support function in REALvision Pro allows you to set the support precisely with a paint brush on the 3D model. The paint brush size is adjustable with an easy to use slider. You can use the erase tool to remove the unwanted structures with the same precision. Perfect for the finest details.

The golden middle way - a combination of automatic and customized support

You can also combine automatic support and paint-on support. Use the paint-on support function to adjust the automatically set support structures. You don’t have to start from scratch and you can still customize the support precisely, by removing or adding more.

Adjustable support parameters - customized to your 3D model

Besides the placement of the support structures you can also adjust the support parameters such as support offset or support infill density. Support offset ensures that the support structure does not fuse with the printed object. High infill density support will create a more stable support, which will give better support under overhangs, but will be more difficult to remove and increase the print time.

Expert tip: Automatic infill connections in support - for increased strength

Automatic infill connections means that REALvision Pro will make sure infill lines are connected at the ends within the support. Connecting infill lines at the end, also known as “infill overlap,” means that each layer’s infill lines are extended to meet the previous layer’s lines, forming a continuous path. This approach can provide several benefits such as increased strength, better adhesion and reduced printing time.

You can also specify the length of additional infill before and after infill lines. These will follow the shape of the contour. The distance of these connecting lines can be defined in the field “Leading/trailing infill line length”.

Reliable software supported by real 3D printing experience

Experience behind the trusty toolbox is the key to success. The software is based on the REALvision core, which is the backbone of the slicing software for a decade serving printer manufacturers as a white-label software. There is a team of experts who knows 3D printing from the inside out, continuously working on updates and new features. They are not only writing codes but constantly testing material, print settings, and experimenting. This is the expertise that REALvision Pro customers can access without risking their problems being posted in an online forum.