3D print quality troubleshooting guide

Improve the quality of your 3D-printed parts. A guide on how to fix the most common problems.

What to do when no filament is extruded

The problem is that the printer does not extrude any filament when printing. In this case we need to think of the following possibilities.

Clogged print head

Sometimes little pieces of filament or particles can get stuck within the nozzle on the print head. When this happens the printer cannot extrude any filament, or will only extrude filament irregularly. To solve this problem, you need to unclog the printer. Doing a filament change at a higher temperature than normal can often be enough to unclog the printhead. However, if this fails, the printhead might have to be dismantled. For further instructions, contact your reseller.

The filament is entangled

The filament can sometimes get entangled, resulting in the printer not being able to extrude the filament. If this happens, try to disentangle the filament.

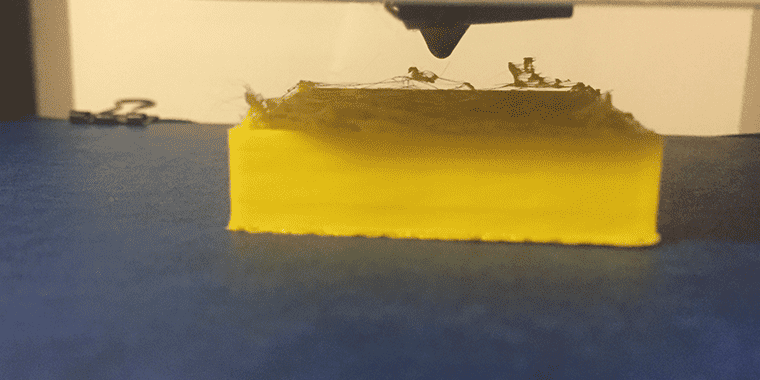

Nozzle too close to the print bed

The nozzle might be too close to the print bed, there is not enough space for the material to come out. If this is the problem you will see that the printer will start to extrude after a few layers as the Z-axis changes and the bed lowers accordingly. You can adjust the print bed (Z-axis) in Printer settings/Bed leveling. The bed leveling method should be set to Automatically – if your printer supports it.

The extruder was not primed

The extrusion might be delayed if the printer was heated up ready to print for a while but was not in use. The melted material has been leaking out from the hot nozzle, creating an empty channel on its way. To solve this issue, you should prime your extruder right before beginning a print so that the nozzle is ready to extrude material to its full potential. The easiest way to do this is to print a brim, an extra wide bottom layer around your object, that can be easily removed afterwards. You can set brim in REALvision Pro in the Printing Settings/Expert level/Bed Adhesion tab.

Printing settings in REALvision Pro

You can find the Printing Settings in REALvision Pro on the left panel as shown on the image on the left. The settings are available on three levels based on the users` experience with 3D printing: Basic, Advanced and Expert.

You can learn more in our Academy.

The printer is out of filament

It sounds basic, but if the printer has run out of the filament on the spool it cannot continue printing. Change the filament and restart the print.

A software program to fit your needs

If you want to get quality prints without doing 3D modeling, consider adding REALvision Pro to your 3D printer kit. We promise you easy-to-use 3D slicing software in the high-end printing industry. Suppose you are:

- A picky hobbyist with a cheap desktop 3D printer.

Running a 3D printing service with flawless 3D prints. - 3D printing metal parts for aerospace.

- 3D printing customizable prosthetics, implants, or casts in ABS plastic (Acrylonitrile Butadiene Styrene).

- Rapid prototyping 3D models from design software.

- Need help with calibration or material profiles.

- Finding the best 3D printer for your application.

- Exploring manufacturing processes and technology to obtain zero-waste.

In that case, we have a software plan fitting your needs.