Voxelfill in practice

Now everyone can get stronger parts from FDM 3D printers using advanced print plugins for REALvision Pro. Following the release of the ADDCAAM plugin by Addman, it’s now the turn of Voxelfill by Aim3D.

Let’s look at the story behind Voxelfill. Fused deposition modeling (FDM) is one of the most widely used 3D printing methods, thanks to its accessibility and versatility. Filament is heated and deposited layer by layer, building parts directly from a digital model. The process is clean, safe, and doesn’t require specialized safety gear, making it ideal for workshops, labs, and home setups alike.

Despite its popularity, FDM has inherent technical challenges. Layer adhesion—especially along the Z-axis—and anisotropic strength can limit the performance of printed parts. Improving these aspects through software was Aim3D’s initial goal, and it marked the beginning of a collaborative relationship with Create it REAL.

At Create it REAL, enhancing FDM technology—through smarter toolpaths, optimized material use, and reinforced bonding strategies—has been a mission for years. Early on, we made a strategic decision to remain independent and maintain full control by developing REALvision as the core technology to drive FDM printers. This approach opens the door to stronger, more reliable components and pushes the boundaries of what this already flexible technology can achieve.

So when Aim3D brought the Voxelfill project to the table, it was an obvious match—a collaboration destined to strengthen 3D printing in ways both teams had long envisioned. Together, the hardware experience of Aim3D and the software expertise of Create it REAL created the perfect foundation for a solution that doesn’t just tweak FDM—it redefines what it can deliver.

What is Voxelfill?

Anyone working with 3D printing knows the story: parts are usually strong in the XY plane, but the Z-axis—where layers bond—often becomes the weak spot. This limits how parts can be used in real-world applications. For fiber-reinforced plastics, especially, it means designs that look solid can still fail under vertical stress. Improving Z-strength has been one of the biggest challenges holding additive manufacturing back from its full potential.

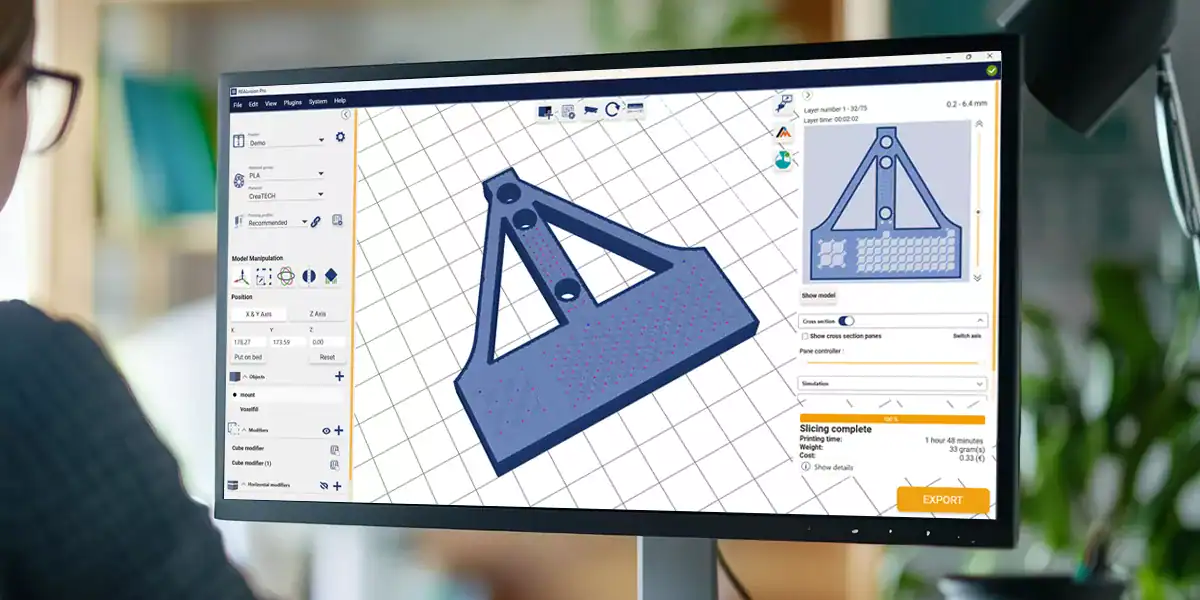

Voxelfill is a new plugin for REALvision Pro that tackles this problem head-on. Instead of just stacking layers in the traditional way, Voxelfill introduces a smart layer-bridging strategy that strengthens the bonds between them. The result is a big leap in durability: in testing, parts reached up to 81% of XY strength in the Z direction—a level of isotropic strength that was previously out of reach. And the best part? Voxelfill works on common printers, not just specialized industrial setups.

This makes it especially powerful for fiber-reinforced materials such as PETG GF30, where higher strength opens doors to applications once thought impractical for FDM. Consider end-use brackets, fixtures, or components in demanding fields like automotive and healthcare, where safety and performance rely on strength in every direction.

From FormNext to your workshop

At FormNext last year, Aim3D showcased Voxelfill live on a Bambu Lab printer. The message was clear: this isn’t a lab-only experiment—it’s a feature designed for everyday 3D printing. By running on an accessible, widely available machine, they proved that Voxelfill empowers anyone—not just those with high-end equipment—to create stronger parts.

REALvision Pro extends this accessibility even further. It supports not only Bambu Lab printers but also a wide range of the most common 3D printers for both industrial and personal use. And that’s not all: every user can create their own printer profile and even have it verified by our support team for added confidence. This makes Voxelfill not just a breakthrough feature, but one that scales across the full spectrum of FDM—from professional prototyping labs to small workshops and even hobbyist spaces.

How it works in practice

The principle is simple but powerful. Voxelfill generates a toolpath that bridges between layers, weaving the structure together in a way that resists vertical stress. Combined with fiber-reinforced plastics like PETG GF30, the difference is easy to see—parts that used to split along layers now hold up under real loads.

This isn’t just theory—it’s been validated through extensive testing, with results confirmed in collaboration with industry partners. The fact that this is achieved through software innovation means there’s no need for extra hardware, exotic materials, or complex post-processing. Just better parts, right off the printer.

Results you can count on

With Voxelfill, you can:

- Reach up to 81% Z-strength compared to XY strength

- Produce parts that are stronger and more durable in real-world use

- Unlock new applications for fiber-reinforced materials

- Work with common hardware without extra complexity

This isn’t just an incremental step forward—it’s a shift in what’s possible with FDM. By addressing one of the technology’s biggest weaknesses, Voxelfill turns FDM into a solution for applications that once required alternative methods.

Ready to try Voxelfill?

Voxelfill is now available as a plugin in REALvision Pro. Whether you’re developing prototypes or producing end-use parts, you can print with confidence knowing your designs are strong in every direction. And with REALvision Pro’s growing ecosystem of advanced plugins—like ADDCAAM and now Voxelfill—you have a toolkit designed to push additive manufacturing forward, one smart layer at a time.