Unlocking stronger, less porous FDM prints with ADDCAAM™

FDM printing is widely used for its accessibility and cost-effectiveness, but challenges like weak layer adhesion and porosity can limit its potential. The ADDCAAM™ plugin overcomes these issues with a multi-patented slicing technology that enhances part strength and density—without changing materials or hardware.

By integrating ADDCAAM into your workflow, you can:

- Achieving higher strength on parts (with better Z strength)

- Reduce parts porosity

- Creating watertight parts

- Achieving a higher strength-to-weight ratio (with targeted strength)

- Moving FDM printing from prototypes to genuine parts

We take a closer look at how ADDCAAM works, including its user-friendly panel and advanced slicing strategies such as interlaced contours, interlaced infill, and optimized top/bottom layers.

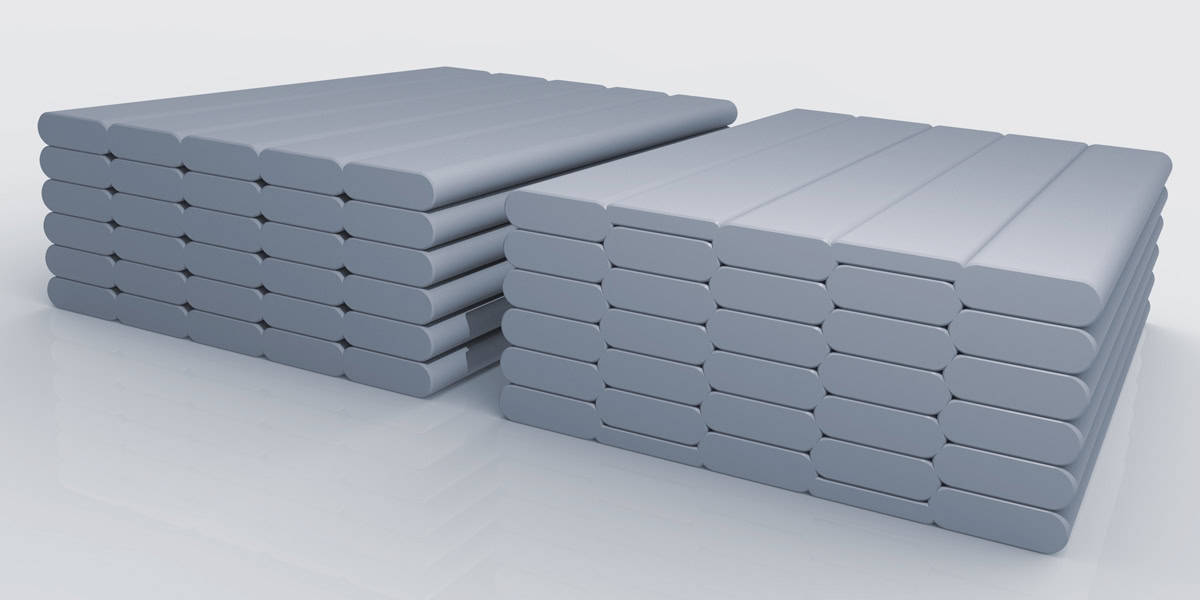

Interlaced contours: stronger layer bonding, less porosity

InterLace is an advanced bead stacking method that uses a non-coplanar layering technique to alternate bead heights, creating interlocking layers. This eliminates continuous stress paths in traditional planar printing, significantly reducing porosity.

The result? Parts that are both air- and watertight—something extremely difficult to achieve with standard FDM methods.

The process starts with alternating half-height or one-and-a-half-height bead layers, followed by full-height beads that interlock with previous layers. This forms a dense, cohesive structure that:

- Eliminates stress risers and weak points

- Improves mechanical integrity

- Ensures consistent part density

- Reduces the risk of delamination

Interlocking infill: better load distribution and durability

InterLocking InFill strengthens internal structures by alternating infill paths in every other layer. This sandwich infill layers within structural walls, locking them into place and creating a more monolithic, cohesive part.

When combined with InterLace, this technique:

- Enhances part strength and durability

- Improves load distribution

- Optimizes material use

Directional interlaced infill: strength where it matters most

InterLace technology extends beyond contours to infill patterns, allowing directional interlaced beads. The ADDCAAM plugin enables users to control bead orientation, and when combined with REALvision Pro’s modifier concept, it allows multi-directional infills within the same part. This unlocks new possibilities for strength optimization tailored to specific load requirements.

Overflow factor: fine-tuning material flow

With ADDCAAM, material flow can be increased thanks to improved bead stackability. A dedicated overflow factor helps reduce porosity while ensuring a more compact and solid part structure.

Gradient flow: maintaining surface finish and tolerances

ADDCAAM introduces a gradient flow factor for top and bottom layers to preserve surface quality and dimensional accuracy. This ensures a smooth finish without compromising strength, keeping parts functional and visually refined.

A user-friendly interface for easy optimization

The ADDCAAM™ plugin offers an intuitive interface where all settings are conveniently accessible. A cut-view simulation allows users to inspect the strengthened part before printing, ensuring full control over the final result.

With ADDCAAM, FDM printing moves beyond traditional limitations—unlocking new possibilities for strength, density, and real-world functionality.

Bringing FDM printing to the next level

With ADDCAAM, FDM printing is no longer limited to prototyping—it’s a viable option for strong, functional, and even watertight parts. By enhancing layer adhesion, reducing porosity, and allowing precise control over material flow and strength distribution, ADDCAAM unlocks new possibilities for engineers and manufacturers.