3D printing is for everyone - hidden complexity, intuitive user interface

The time is over when 3D printing was an expensive tool for super smart engineers and Fortune 500 companies. The technology is only a fingertip away from all mortal humans. In REALvision Pro, our approach is to give as much guidance as possible to our users to make it easy to get great printing results. This allows excellent outcome even with basic settings. At the same time, we also think of users with advanced 3D printing experience. Therefore it is also an option to use advanced and even expert settings to get into the finest details of 3D printing.

Read below how REALvision Pro offers a user friendly interface that can be customized to the users’ level of expertise in 3D printing.

Settings tailored to level of 3D printing expertise

Besides having a great tool set it is also important to easily get around in your tool shed. A simple and consistent user interface helps the user to find the settings of the level of expertise needed. The settings are grouped into three categories based on experience with 3D printing and increasing complexity: Basic, Advanced and Expert level categories. This allows a smooth interaction for every user from beginners to experts.

Let’s take the example of setting the Material properties.

- On the Basic level, the Material properties settings are reduced to two settings: Material (material density, material price) and Temperatures (printing temperature, heated bed).

- On the Advanced level: Material (material density, material price), Temperatures (printing temperature, heated bed), Flow (max. extrusion), Cooling (min. Time per layer, fans, max. Fan speed), Retraction (push-out, suck-back, repositioning), and Priming settings (priming distance, priming speed…)

- On the Expert level, all these are completed with Layer thickness settings (max., min. Layer height)

The increasing complexity of settings helps users to match the difficulty to their expertise with 3D printing.

Easy access to printer profiles and material profiles

It is always a crucial question whether a 3D printing software supports your 3D printer. In REALvision Pro you can easily set up your own 3D printer model and printing material, so your 3D printer is ready to exploit all the features and capabilities.

Users of REALvision Pro can easily access their printer (1) and material profiles (2), making it smooth to switch from one to another. Aligned to the different levels of expertise they can go with existing preset profiles or create their own customized profiles.

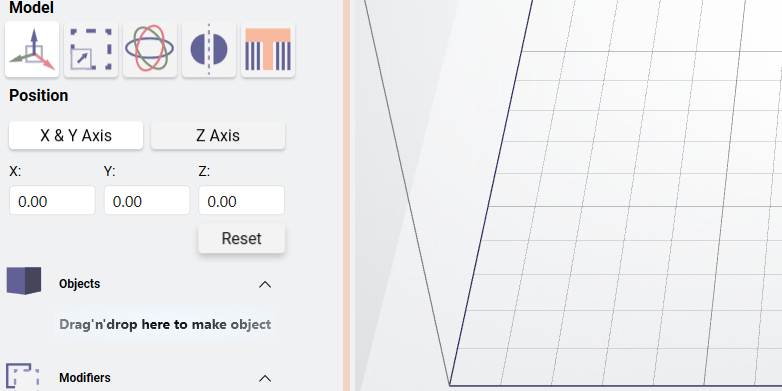

Object modification made it easy

The object modification tools are stored in an easy-to-use panel with icons illustrating the purposes of the tools. The objects can be moved (1), scaled (2), rotated (3) and flipped (4) both by setting the extent of change by entering numerical values or manually by clicking on the object and dragging it to the desired degree.

Objects (6) can be also renamed to make it easy to differentiate them in case there are more of them on the build plate. Customizable support (5) work with the ease of painting the support manually on the objects.

Overall users can get around the whole interface with the ease of playing on a playground.

Slicing preview to avoid surprises

The printing result should not be a surprise to the users of REALvision Pro. The slicing preview shows the 3D model layer by layer with different colors illustrating the contours, infill, support, raft and repositioning. This helps the users to visualize the printing process and the result in advance. In a separate panel the estimated printing time, filament usage and weight is shown. Thanks to the precise estimation users can exactly know what to expect.

Reliable software supported by real 3D printing experience

Experience behind the trusty toolbox is the key to success. The software is based on the REALvision core, which is the backbone of the slicing software for a decade serving printer manufacturers as a white-label software. There is a team of experts who knows 3D printing from the inside out, continuously working on updates and new features. They are not only writing codes but constantly testing material, print settings, and experimenting. This is the expertise that REALvision Pro customers can access without risking their problems being posted in an online forum.